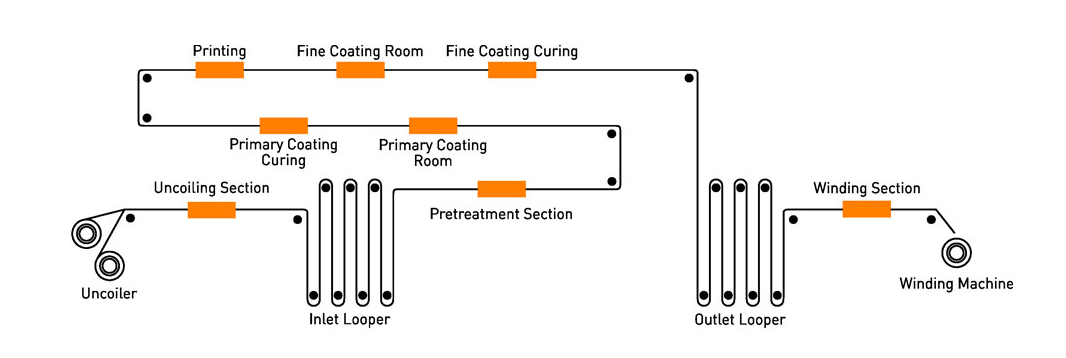

The company's production line includes two core parts:

1. Coating Unit

2. Printing Unit

The structure and process of the coating machine are produced using advanced design concepts from south Korea, and the entire line is produced using electronic control equipment from Siemens in Germany. Adopting the three coating and three drying process, the surface quality, coating accuracy, and processing performance of color coated products have reached international leading levels.

The printing unit is designed and manufactured by a professional Korean company, perfectly achieving three color overprinting, which is superior to other ordinary monochrome color coating technologies. The printing effect is rich and can achieve multi-level, concave and convex, and three-dimensional effects. It can simulate the effects of other materials such ad wood, stone, fabric, leather, stainless steel, copper, etc.

| Base Metal Thickness | 0.2mm – 1.2mm |

| Coil Width | 800mm – 1600mm |

| Coil Internal Diameter | 508mm & 610mm |

| Coil Weight | Max: 8MT |

| Metallic Coating | Z60 – Z275 & AZ60 – AZ180 |

| Thickness of Organic Coating | 20micro – 45micro |

| Yearly Production Capability | 100000MT/Year |

Customized coating system available

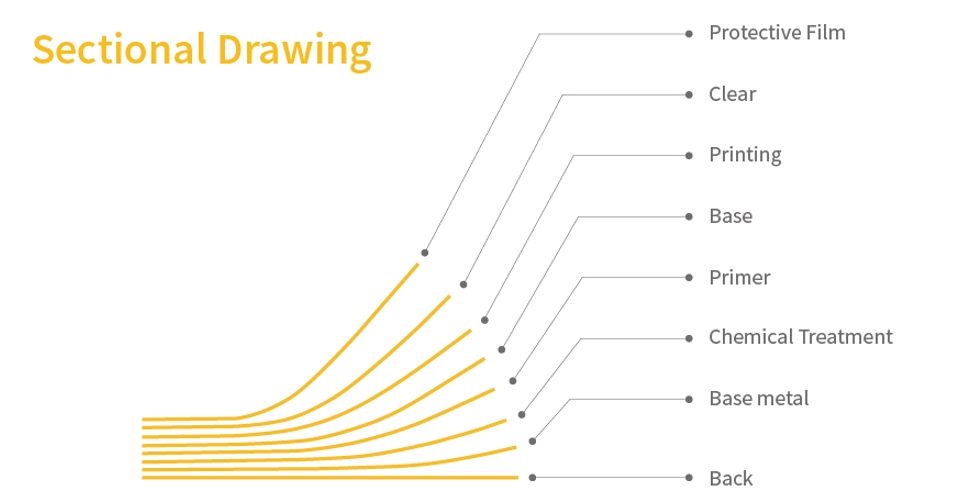

2-coat or 3-coat top coating ( Primer + Top coat + Finishing coat )

Primer / primer + top coating for back side

Two sides color–coated allowed

Protection film as optional

Color-matching service provided